JGaulard

Administrator

Staff member

Site Supporter

Sr. Site Supporter

Power User

- Joined

- May 5, 2021

- Messages

- 319

- Reaction Score

- 2

- Points

- 18

- #1

We recently installed a wood pellet stove during a cold snap and ran it all night. The pellet stove was working fine, but after I woke up in the morning, I began wondering why in the world the water wasn’t working and why it was so cold in the house. We still have oil heat and that should’ve kicked in, keeping the house at least 50 degrees.

To see what was wrong with the heat, I went downstairs and took a look at the boiler. I noticed that one zone pump was turning, but the pipes feeding the baseboard heat weren’t hot. I immediately thought, “frozen heating pipes.” I walked over and flipped the red emergency boiler switch to the “off” position.

I walked upstairs and started turning on faucets to see what was wrong with the house water. None of them worked. No showers, no sinks, no toilets. I thought again, “frozen pipes.”

I then thought back to the post I had written two days prior. I thought of one specific line, ” The last thing I’d like to do is to sit here listening to the sounds of pipes freezing in the house.” Well, there we were, a house that minutes before had no heat and a house that had its complete plumbing system shut down. Now mind you, the previous night’s temperature was down to -1 degrees and it was only 0 when we woke up. The house was very cold.

I walked around and found Laura. I told her that since I had no idea where the pipes were frozen, I was unable to make any repairs. We would have to wait for things to thaw out. We’d have to let the pellet stove do its work.

There are interesting questions here that need to be answered. One question is, “Why didn’t the oil heat kick on when the boiler was clearly working?” Another is, “Why did the baseboard heating pipes freeze?” Well, the answers are, when you supplement a house that already is equipped with baseboard (water) heat with a pellet stove, you essentially take the heating function away from the boiler until the house temperature reaches about 40 degrees. We turned the thermostats way down since we didn’t need the oil heat anymore.

The problem with this is, if the pellet stove goes out and the house temperature falls too low, things are already past the point of saving. The interior of the house falls slower than the exterior walls (where the upstairs baseboard heating pipes run) and any area where there may be a draft. If any copper tubing is exposed to a cold draft, it risks freezing. Since the interior of the house dropped to 44 degrees, the baseboard heating pipes already froze, thus making hot water flow though them impossible. Lesson learned. I guess it’s either full time oil heat or not. Interesting. Especially when the temps fall below 5 degrees.

After about an hour, the pellet stove raised the temperature inside to about 50. Right after I noticed that, I heard a gurgle and then the sound of spraying water. Burst pipe number one located. It was behind the shower in the downstairs bathroom. Good thing there was a section of wall that was easily removed.

When I opened the wall, I found what I thought was a leak in one bad pipe. I cut the pipe and put one of the 3/4″ SharkBite valves I happened to pick up a few days earlier on its end. Boy, lucky I had them.

By the way, before I did any of this, I turned off the main water valve.

As I was working on this pipe, gee whiz, another pipe started squirting water. It was the “hot” line of the shower. I did the same thing for this one. Cut the pipe and attached the other SharkBite valve I had.

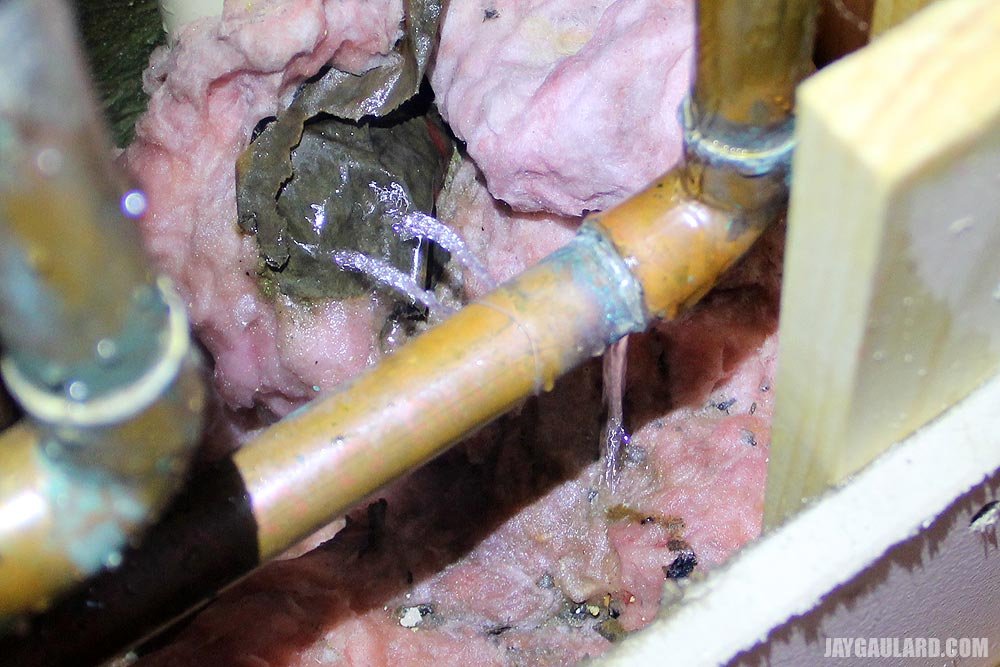

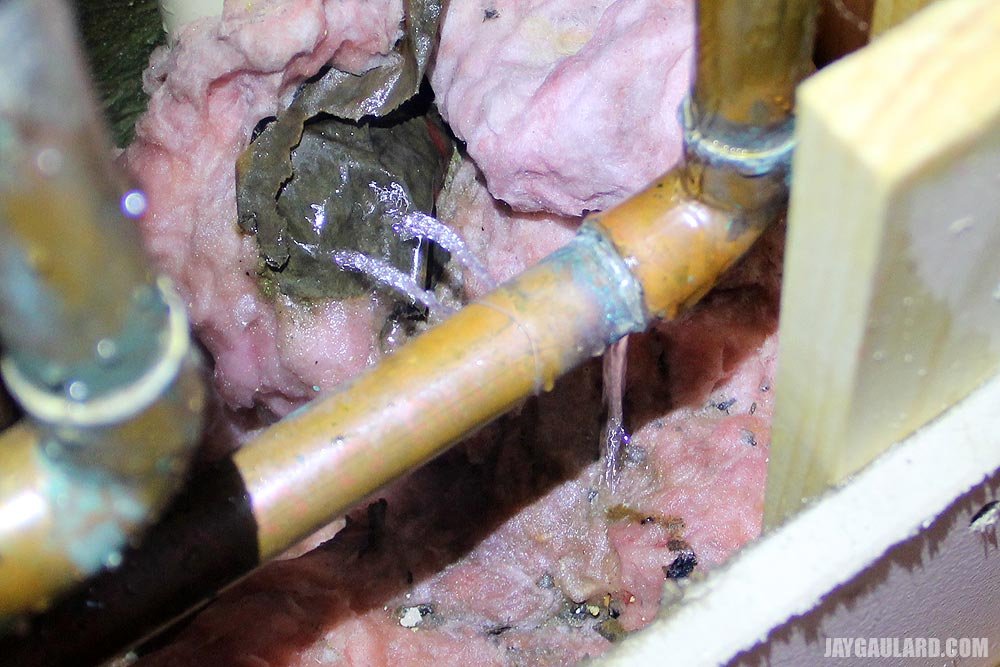

Here are a few pictures for you just in case you aren’t aware of what it looks like when a copper pipe bursts from freezing.

I knew I needed to get these pipes fixed because I had a feeling they weren’t the only ones that would need repair.

I pulled out my torch and went to work. Luckily I had some spare copper pipe and fittings. I also had flux and solder. After a few minutes, I had the whole area soldered and repaired. I also stuffed insulation in the offending opening that was allowing the draft to flow under the tub. I’m hoping that has a positive effect.

One problem solved. The downstairs water was working. The upstairs water still was not working and neither was the baseboard heat.

A few hours later, I heard it raining in the downstairs bathroom. Frozen area number two found. The same thing happened behind the bathtub upstairs. Since I didn’t know where the leak was coming from, I was forced to rip down part of the ceiling in the bathroom. Once I had access, I could see that the leak was coming from upstairs. I did the same thing – I removed the access panel behind the tub, cut out the old pipe and soldered in a new one using the same joints.

In this case, the 3/4″ copper pipe shown above burst. There was another smaller 1/2″ pipe that burst as well. Since I didn’t have any spare 1/2″ tubing, I simply heated the “T” adapters and turned the pipe so the split was on top. I cleaned the area with a wire brush, applied some flux and brazed the area. It’s holding for now until I can repair it properly.

The water in the house is now working. Here’s the thing – the baseboard heat still doesn’t work in two zones. It’s frozen. I’m not sure it’s going to thaw either. The way the house was outfitted with the heating pipes was done in such a way that we’ll never be able to have a supplemental heat source without the pipes freezing. Because of this, I’m planning on purchasing a six foot and a five foot length of baseboard heat and attaching those two units to two interior walls. I’ll simply cut the existing pipes that feed the downstairs zone and feed them to the new zone I create. But that won’t be until next week. In the meantime, we’ve got a blizzard ready to hit tonight and tomorrow and temperatures reaching all the way down to -14 degrees on Monday or Tuesday. Oh, the drama. I already went out to Tractor Supply this afternoon for two backup heaters. One electric and one propane. Perhaps one day we’ll have one of every kind.

What’s the moral of this story? Get a wood burning stove. There really is no alternative.

To see what was wrong with the heat, I went downstairs and took a look at the boiler. I noticed that one zone pump was turning, but the pipes feeding the baseboard heat weren’t hot. I immediately thought, “frozen heating pipes.” I walked over and flipped the red emergency boiler switch to the “off” position.

I walked upstairs and started turning on faucets to see what was wrong with the house water. None of them worked. No showers, no sinks, no toilets. I thought again, “frozen pipes.”

I then thought back to the post I had written two days prior. I thought of one specific line, ” The last thing I’d like to do is to sit here listening to the sounds of pipes freezing in the house.” Well, there we were, a house that minutes before had no heat and a house that had its complete plumbing system shut down. Now mind you, the previous night’s temperature was down to -1 degrees and it was only 0 when we woke up. The house was very cold.

I walked around and found Laura. I told her that since I had no idea where the pipes were frozen, I was unable to make any repairs. We would have to wait for things to thaw out. We’d have to let the pellet stove do its work.

There are interesting questions here that need to be answered. One question is, “Why didn’t the oil heat kick on when the boiler was clearly working?” Another is, “Why did the baseboard heating pipes freeze?” Well, the answers are, when you supplement a house that already is equipped with baseboard (water) heat with a pellet stove, you essentially take the heating function away from the boiler until the house temperature reaches about 40 degrees. We turned the thermostats way down since we didn’t need the oil heat anymore.

The problem with this is, if the pellet stove goes out and the house temperature falls too low, things are already past the point of saving. The interior of the house falls slower than the exterior walls (where the upstairs baseboard heating pipes run) and any area where there may be a draft. If any copper tubing is exposed to a cold draft, it risks freezing. Since the interior of the house dropped to 44 degrees, the baseboard heating pipes already froze, thus making hot water flow though them impossible. Lesson learned. I guess it’s either full time oil heat or not. Interesting. Especially when the temps fall below 5 degrees.

After about an hour, the pellet stove raised the temperature inside to about 50. Right after I noticed that, I heard a gurgle and then the sound of spraying water. Burst pipe number one located. It was behind the shower in the downstairs bathroom. Good thing there was a section of wall that was easily removed.

When I opened the wall, I found what I thought was a leak in one bad pipe. I cut the pipe and put one of the 3/4″ SharkBite valves I happened to pick up a few days earlier on its end. Boy, lucky I had them.

By the way, before I did any of this, I turned off the main water valve.

As I was working on this pipe, gee whiz, another pipe started squirting water. It was the “hot” line of the shower. I did the same thing for this one. Cut the pipe and attached the other SharkBite valve I had.

Here are a few pictures for you just in case you aren’t aware of what it looks like when a copper pipe bursts from freezing.

I knew I needed to get these pipes fixed because I had a feeling they weren’t the only ones that would need repair.

I pulled out my torch and went to work. Luckily I had some spare copper pipe and fittings. I also had flux and solder. After a few minutes, I had the whole area soldered and repaired. I also stuffed insulation in the offending opening that was allowing the draft to flow under the tub. I’m hoping that has a positive effect.

One problem solved. The downstairs water was working. The upstairs water still was not working and neither was the baseboard heat.

A few hours later, I heard it raining in the downstairs bathroom. Frozen area number two found. The same thing happened behind the bathtub upstairs. Since I didn’t know where the leak was coming from, I was forced to rip down part of the ceiling in the bathroom. Once I had access, I could see that the leak was coming from upstairs. I did the same thing – I removed the access panel behind the tub, cut out the old pipe and soldered in a new one using the same joints.

In this case, the 3/4″ copper pipe shown above burst. There was another smaller 1/2″ pipe that burst as well. Since I didn’t have any spare 1/2″ tubing, I simply heated the “T” adapters and turned the pipe so the split was on top. I cleaned the area with a wire brush, applied some flux and brazed the area. It’s holding for now until I can repair it properly.

The water in the house is now working. Here’s the thing – the baseboard heat still doesn’t work in two zones. It’s frozen. I’m not sure it’s going to thaw either. The way the house was outfitted with the heating pipes was done in such a way that we’ll never be able to have a supplemental heat source without the pipes freezing. Because of this, I’m planning on purchasing a six foot and a five foot length of baseboard heat and attaching those two units to two interior walls. I’ll simply cut the existing pipes that feed the downstairs zone and feed them to the new zone I create. But that won’t be until next week. In the meantime, we’ve got a blizzard ready to hit tonight and tomorrow and temperatures reaching all the way down to -14 degrees on Monday or Tuesday. Oh, the drama. I already went out to Tractor Supply this afternoon for two backup heaters. One electric and one propane. Perhaps one day we’ll have one of every kind.

What’s the moral of this story? Get a wood burning stove. There really is no alternative.